I get a lot of emails from new wheel shoppers, asking what the differences are between cast aluminum wheels, flow-formed wheels, 1-piece forged wheels, 2-piece forged wheels, and 3-piece forged wheels. I always take my time to explain the differences in construction methods, as I prefer to educate my customers in order to allow them to select the wheels that best fit their needs.

There are predominantly 6 different methods for construction of wheels. Each one varies in quality, weight, strength, and price. There are pros and cons for each type. Hopefully after reading this thread, you gain a better understanding of each.

1. Cast aluminum wheels

2. Flow-Formed / Rotary Forged wheels

3. 1-piece "Monoblock" forged wheels

4. 2-piece welded construction forged wheels

5. 2-piece bolted construction forged wheels

6. 3-piece bolted construction forged wheels

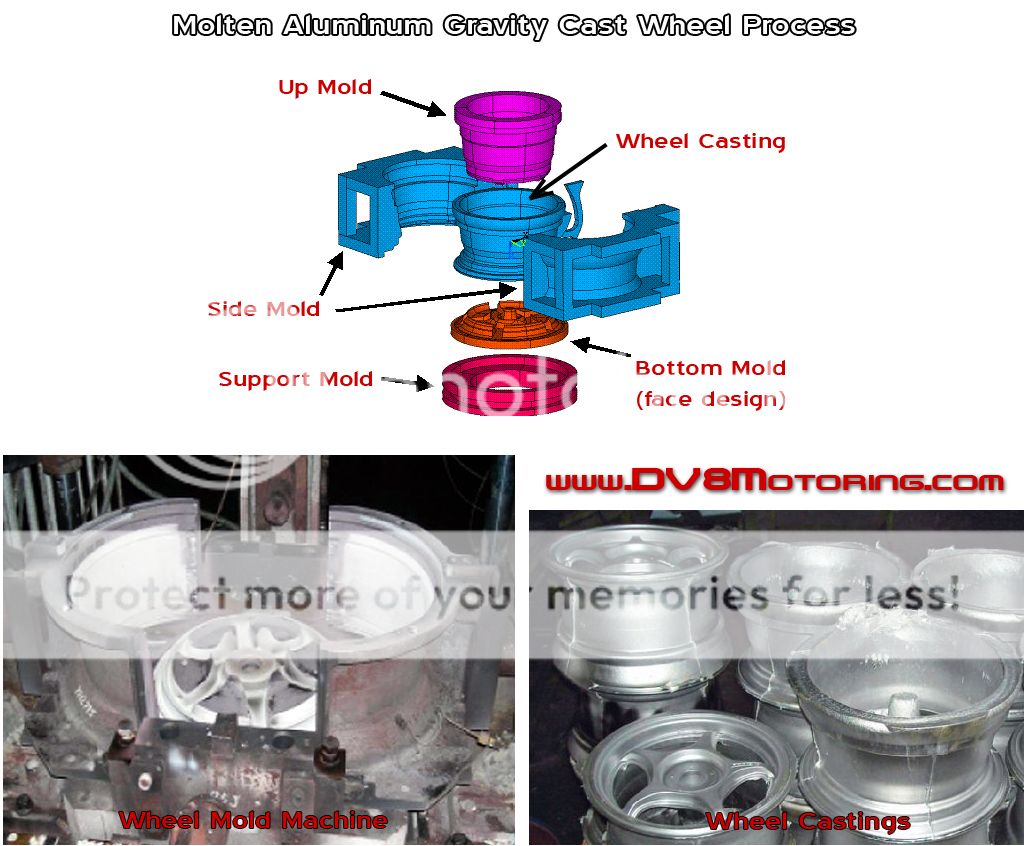

Cast Aluminum Wheels

These are the lowest priced wheels, and are typically what are found on production vehicles. Cast aluminum wheels are created by pouring molten aluminum into a mold that is shaped like a wheel. This produces a wheel casting. Some final machining work is then done to clean up the rough surface, and paint/finishing is applied.

Pros: Lowest price, easiest to mass-produce.

Cons: More brittle than forged wheels. Spoke details and edges aren't as sharp as a machined forged wheel. Heaviest weight of all wheel construction types. Lowest quality. Limited offsets, width increments, diameter selection available. Nearly impossible to repair when cracked or severely bent - safely, that is. A damaged cast wheel usually needs to be replaced.

Flow-Formed / Rotary Forged Wheels

Flow-Formed / Rotary Forged Wheels

Flow-Formed wheels start out identical to cast poured wheels, but with different hoop thickness. The casting process above is used to create the spoke pattern only. Then the wheel castings are put into a flow-forming machine to form the outer hoops. This is done using high heat and high pressure rollers, which "flow-form" the outer hoop. This results in a stronger outer hoop, with aligned aluminum grain structure. The resulting wheel is a cast faced wheel with a hoop that has properties similar to a forged wheel. They are stronger and lighter than cast wheels.

Pros: Low Price, Lightweight, Higher strength than cast wheels.

Cons: Cast face still lacks the sharp edges and details of a machined forged wheel. Limited width increments and diameters available. Hard to repair when severely bent or cracked.

Video on Flow-Forming process:

1-Piece Monoblock Forged Wheels

The term "Monoblock" is used throughout the industry to describe the 1-piece forged wheels. "Mono" meaning one, and "Block" meaning it was created from one block of aluminum. The block in this case is actually a round bar stock of high quality, aerospace-quality 6061-T6 Aluminum Alloy. The round bar is pressed in a huge forging machine, to stamp out a wheel shaped blank. Forging is a hot working process, and helps to align the grain structure of the alloy. This results in a very strong, very lightweight wheel construction material. The wheel blank is then flow-formed to create the outer barrel shape. Following that process, the wheel blank is loaded into a CNC milling machine and there the spoke pattern is milled out.

Pros: Lightest of the forged wheel construction methods.

Cons: Priced about the same as expensive 3-piece construction. Difficult to repair when bent or severely damaged.

2-Piece Welded Construction Forged Wheels

2-Piece Welded Construction Forged Wheels

These are considered the entry level forged wheels, as they are priced slightly lower than 3-piece forged wheels. The centers start out as a blank of forged 6061-T6 Aluminum alloy, and the spoke patterns are CNC machined with a milling machine. The wheel hoop is also a forged aluminum material. On a 2-piece wheel, the center is simply welded to the hoop on the backside of the wheel. Some manufacturers also offer cast aluminum centers, to reduce cost. Quality and weight of the cast centers is not as good as forged/machined, however.

Pros: Lowest Price of the Forged wheels. Same weight, appearance, quality as 3-piece wheels.

Cons: Limited widths increments available. Cannot easily chrome plate or paint the lip, since it has to be welded on. More difficult to repair a bent lip compared to a 3-piece wheel, as the center has to be cut out and a new hoop welded on.

2-Piece Bolted Construction Forged Wheels

These are built very similar to the 2-piece welded construction wheels above, but use a hoop that has a bolting ring already in place. Instead of welding the center to the hoop, it is simply bolted on. This is the least common method of forged wheel construction, as the hoops tend to cost more than simple welded hoops. Some manufacturers also offer cast aluminum centers, to reduce cost. Quality and weight of the cast centers is not as good as forged/machined, however.

Pros: Lips can be easily chrome plated or painted, since no welding required. Easier to replace a hoop when it gets bent.

Cons: Limited width increments available. Few brands offer this type.

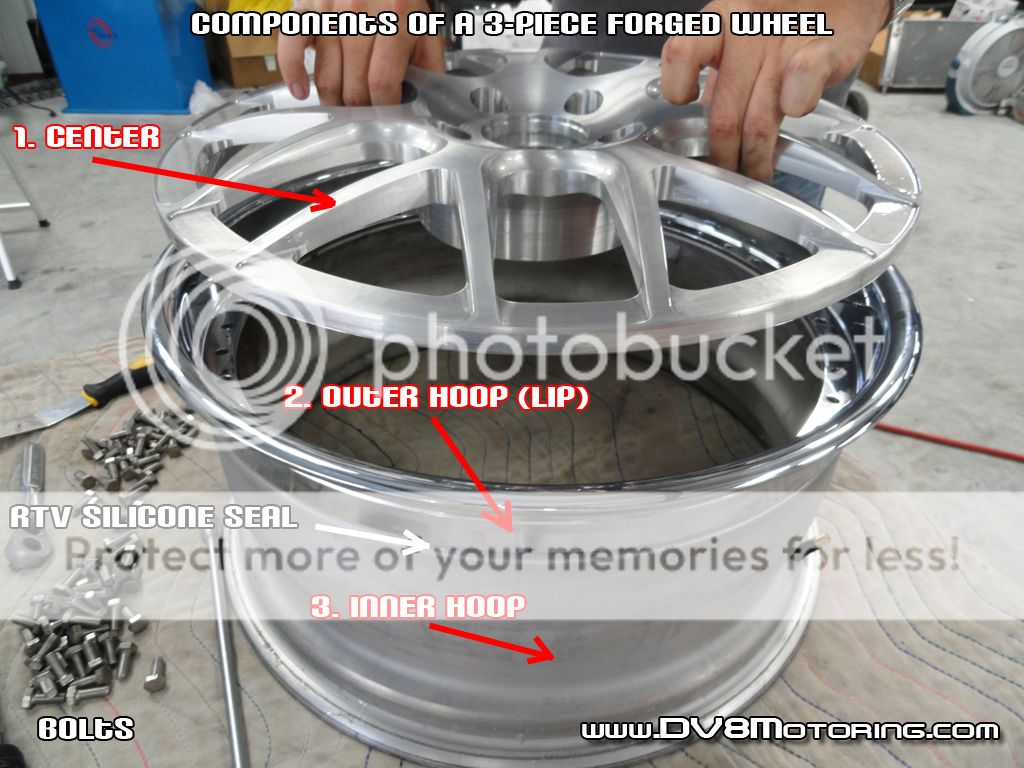

3-Piece Forged Wheels

Three piece forged wheels are usually the most expensive wheel construction, mostly due to the assembly labor and components used. The wheels consist of three main pieces; the center, the outer hoop (lip), and the inner hoop. These three parts are held together with a series of perimeter bolts. Silicone RTV is used to seal between the two hoops. Some manufacturers also offer cast aluminum centers, to reduce cost. Quality and weight of the cast centers is not as good as forged/machined, however.

Pros: Most width increments available, truly perfect fitments available. Easiest of all wheels to repair if lip gets bent or damaged, as hoops are easy to replace. Easy to paint or chrome plate lip, since no welding is required. Can have different color rear hoop and outer hoop, since they are two different pieces. Highest resale value for used wheels.

Cons: Most expensive forged wheel construction. RTV silicone seal can be damaged by inexperience tire installers, resulting in leaks.

Thanks for reading! Feel free to ask any questions regarding wheel construction, I'll try my best to answer you.

Tony